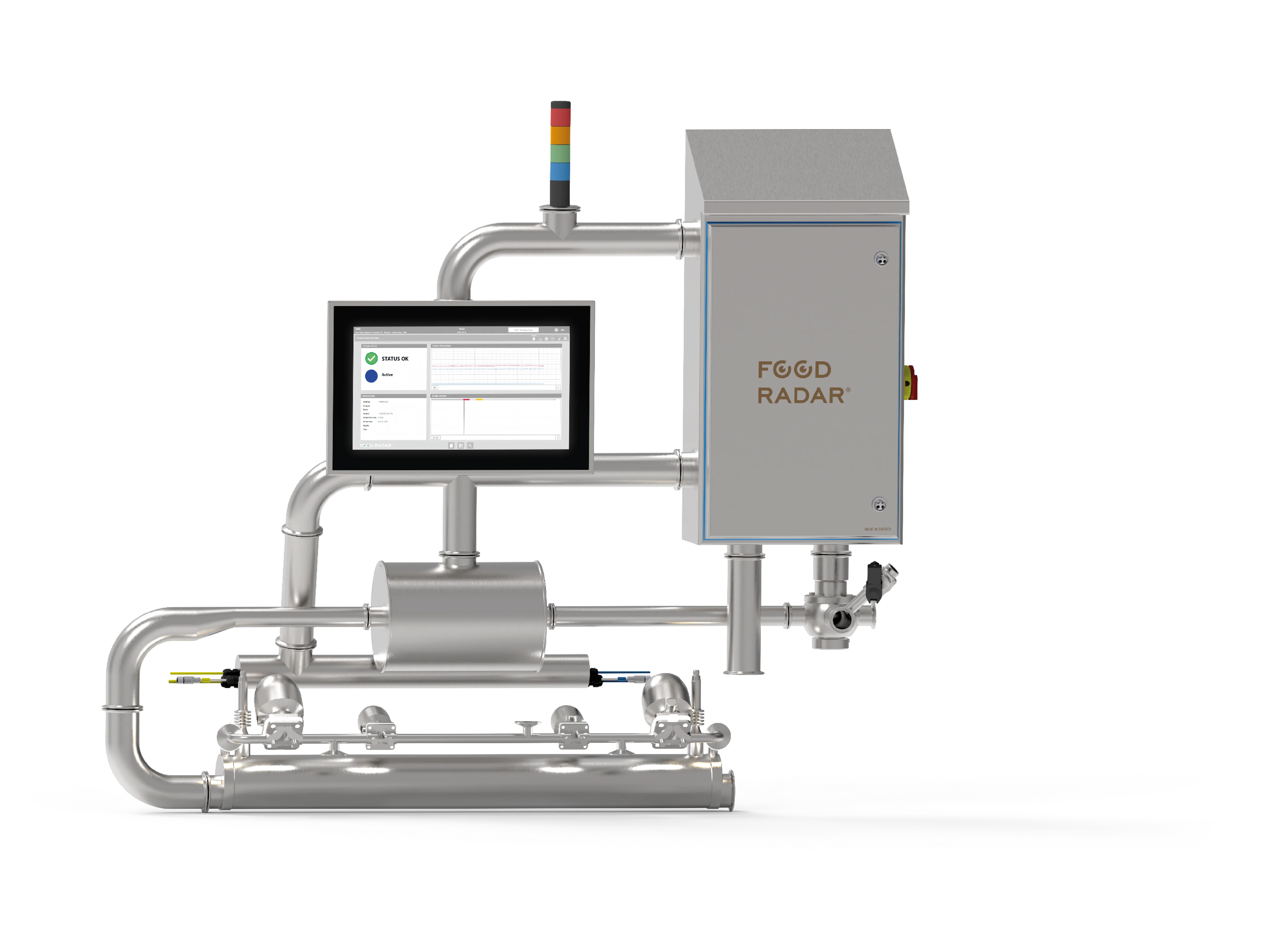

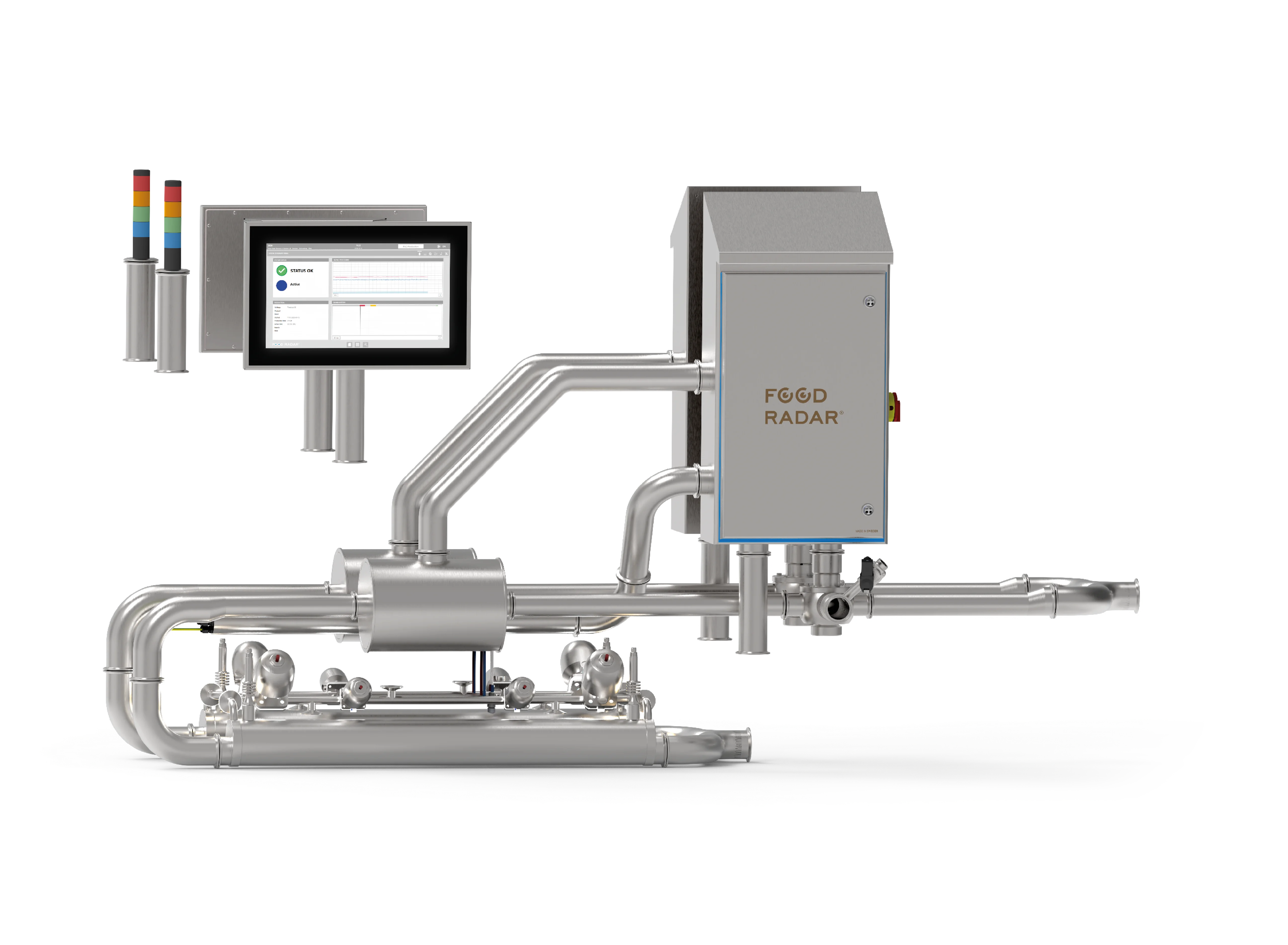

Food Radar® – Unmatched

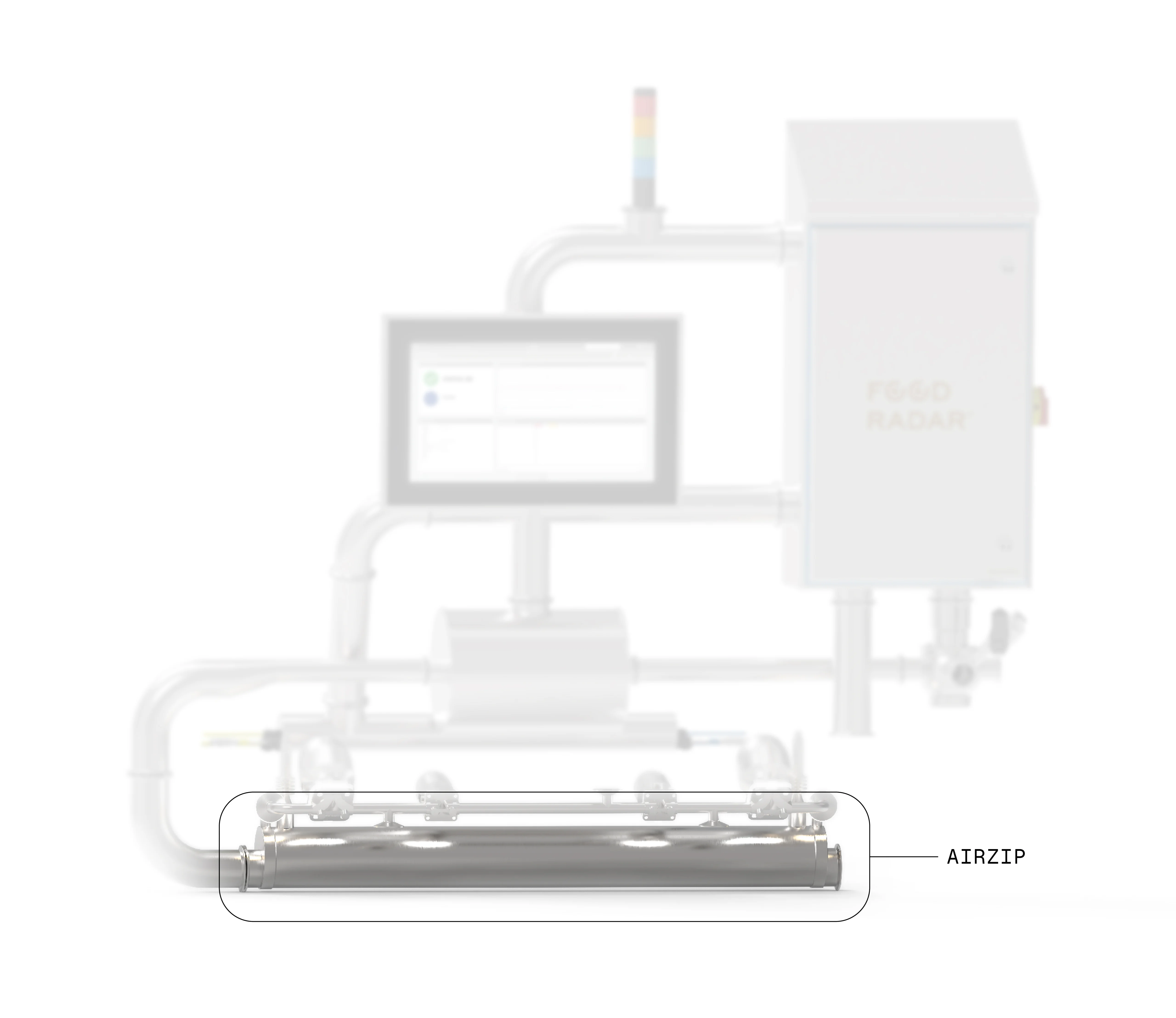

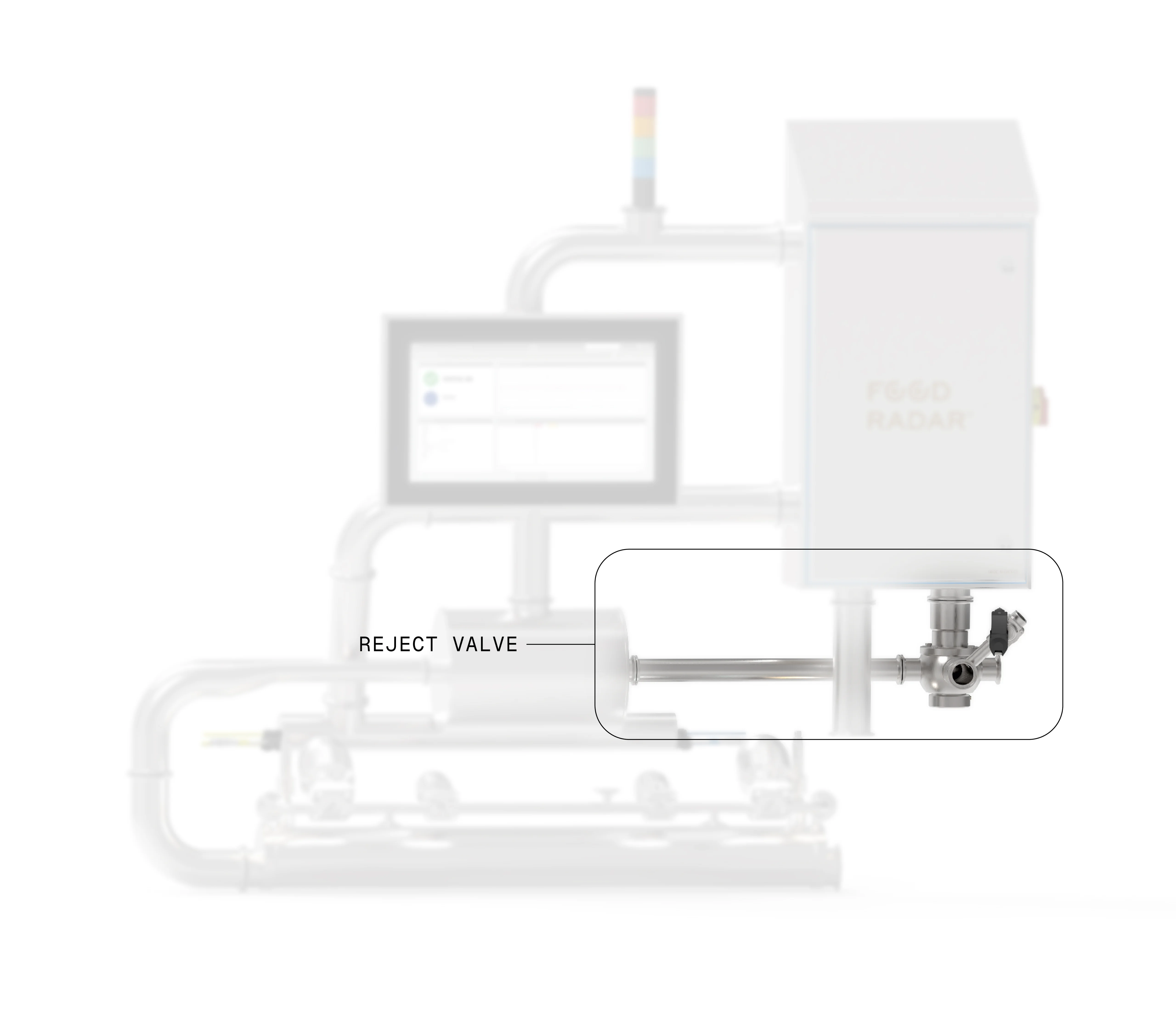

The all-new Generation IV Food Radar® is powered by a completely redesigned Microwave Processor, that redefines what’s possible on the line. Our clients can expect:

Sharper detection: Pinpoint accuracy that catches what others miss.

Faster speed reading: Lightning-quick performance to keep your throughput high.

Stronger capacity: Superior detection even in the toughest, high-conductivity products.