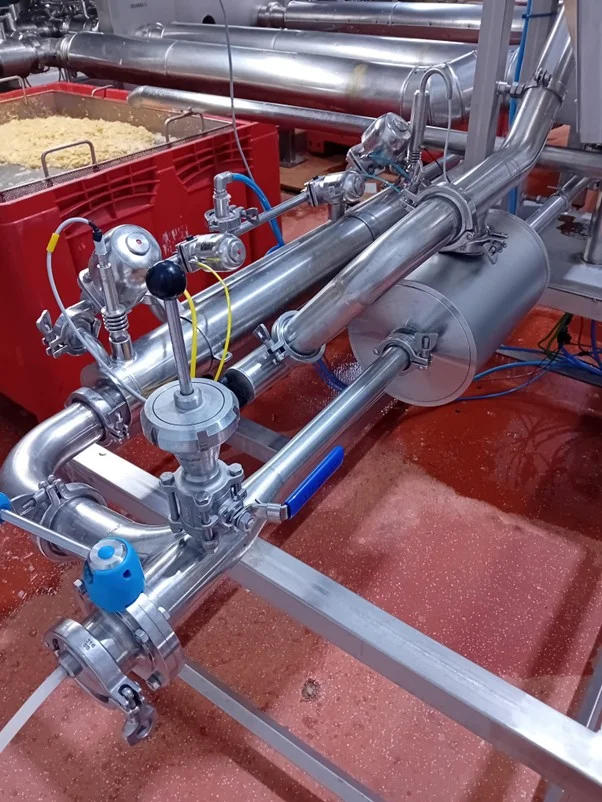

Can you briefly describe your company and your main area of business?

We manufacture processed onion for industry and food service, sold in various aseptic packaging. Its versatile flavor and nutritional properties make it a core ingredient in both agriculture and gastronomy, bringing richness and depth to every dish.