Can you briefly describe your company and your main area of business?

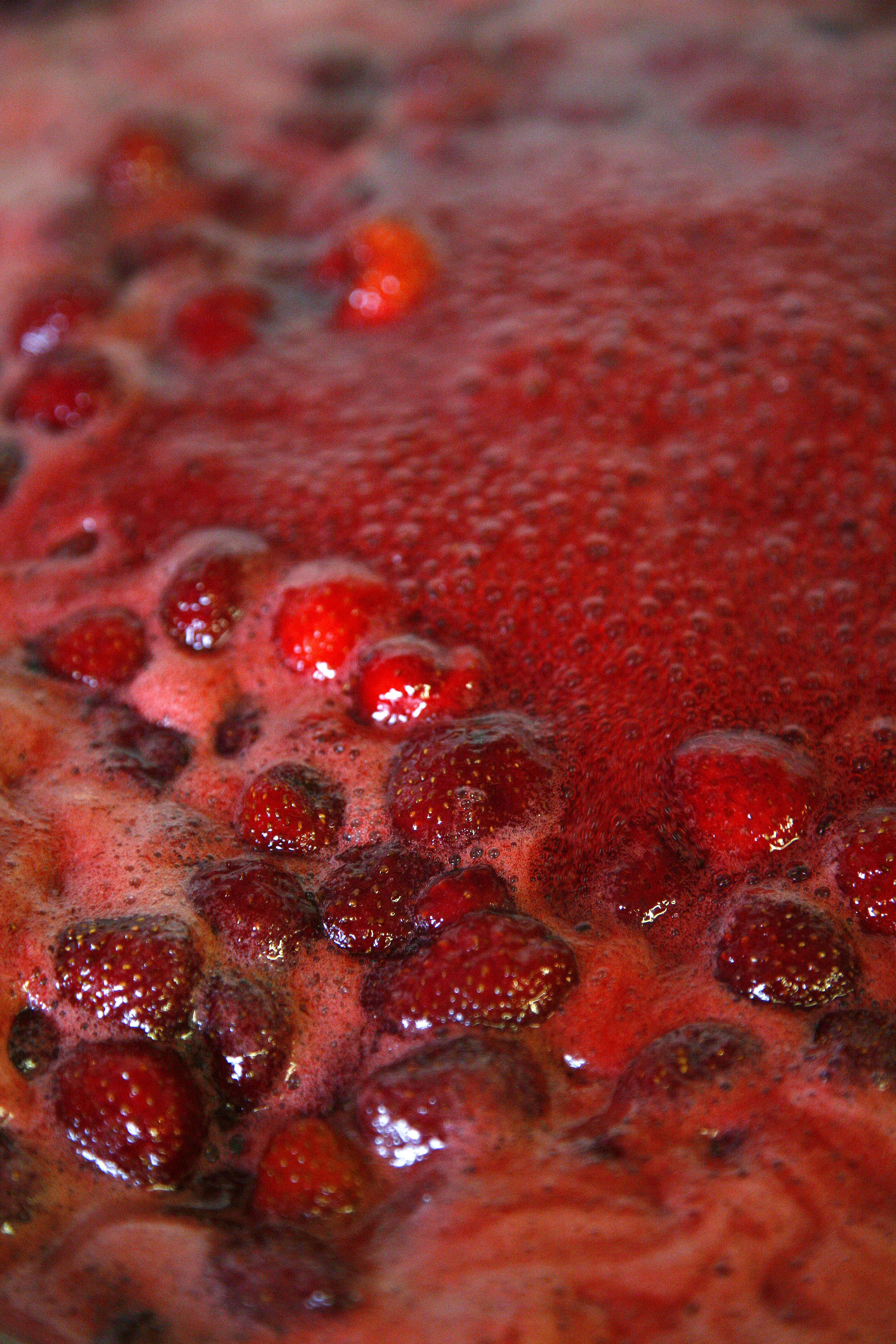

Schwartauer Werke GmbH & Co. KG, founded in 1899 in Bad Schwartau, Schleswig-Holstein, is one of Germany’s leading manufacturers of fruit prod-ucts and snacks. The company offers a diverse portfolio for both the retail and foodservice sectors, including jams, sweet and savory spreads, cereal and protein bars, as well as dessert sauces and syrups. Some of its most well-known brands include Schwartau Extra, Samt, Corny, and Mövenpick Gourmet Fruit Spreads. As the largest employer in the region, this family-owned company employs around 1,000 people across three production sites and achieved annual sales of over 415 million euros in 2024. Since 2002, Schwartauer Werke has been part of the internationally active Hero Group, headquartered in Switzerland and owned by the family of Dr. Arend Oetker. With over 125 years of experience, Schwartauer Werke stands for continuous development and sustainable growth. The company remains future-focused — with a clear commitment to quality, taste, responsibility, and innovation.